THE COMPANY AND THE LASER CUTTING

Ax Professional was founded in 2000 as a company specialized in laser cutting and laser marking.

It also offers complementary processes such as:

- Metal bending with press-bend for sheet metal deformation;

- Metal welding by TIG and MIG welding.

In collaboration with external partners, it boasts numerous finishes: zinc plating, chrome plating, powder coating and catacresi among many others.

The strength of AX Professional is the union of the skills of the highly trained and attentive to the qualitative aspect of the product, to the use of high definition CO2 technology to achieve a high degree of finishing of the cutting edge.

THE COMPANY AND THE LASER CUTTING

Ax Professional was founded in 2000 as a company specialized in laser cutting and laser marking.

It also offers complementary processes such as:

- Metal bending with press-bend for sheet metal deformation;

- Metal welding by TIG and MIG welding.

In collaboration with external partners, it boasts numerous finishes: zinc plating, chrome plating, powder coating and catacresi among many others.

The strength of AX Professional is the union of the skills of the highly trained and attentive to the qualitative aspect of the product, to the use of high definition CO2 technology to achieve a high degree of finishing of the cutting edge.

The finishes

At your discretion, we can deliver raw components, with basic processing such as detachment and deburring, or completely finished, with the additional finishings chosen by you.

These include electroplating, satinizing, micro sandblasting, mirror polishing, electropolishing.

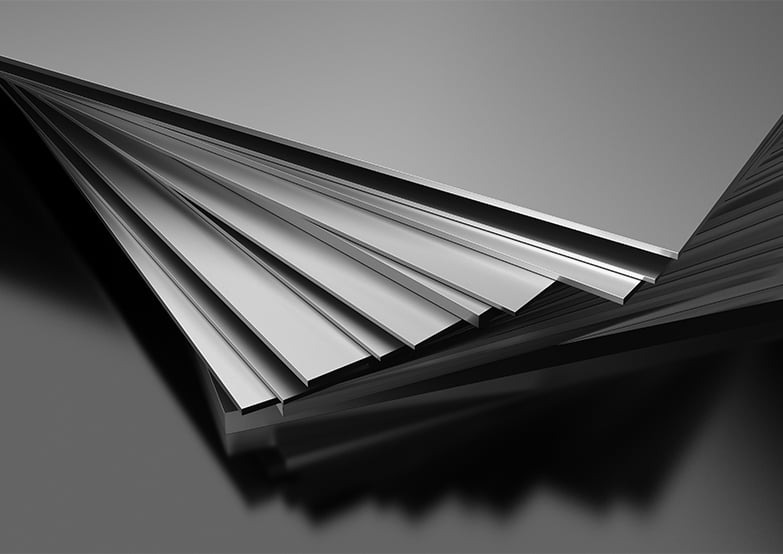

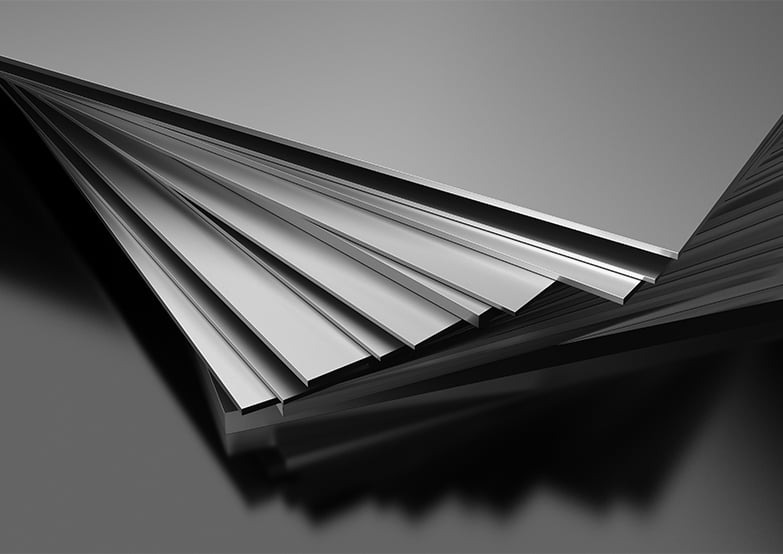

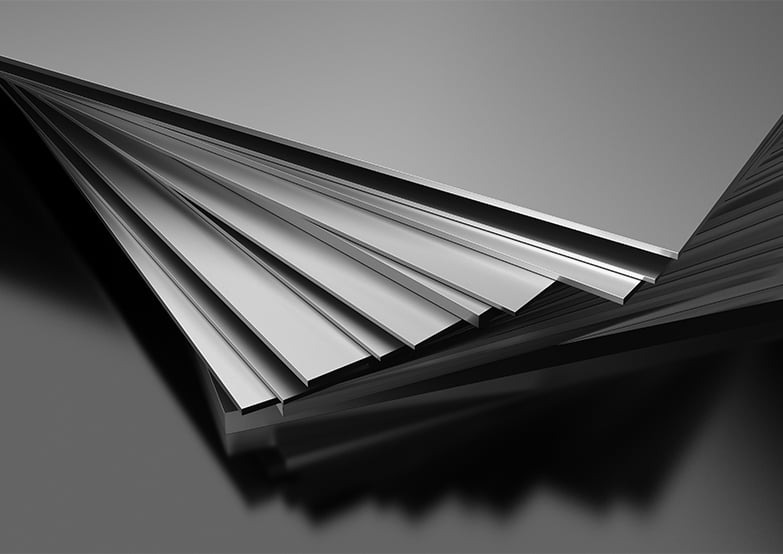

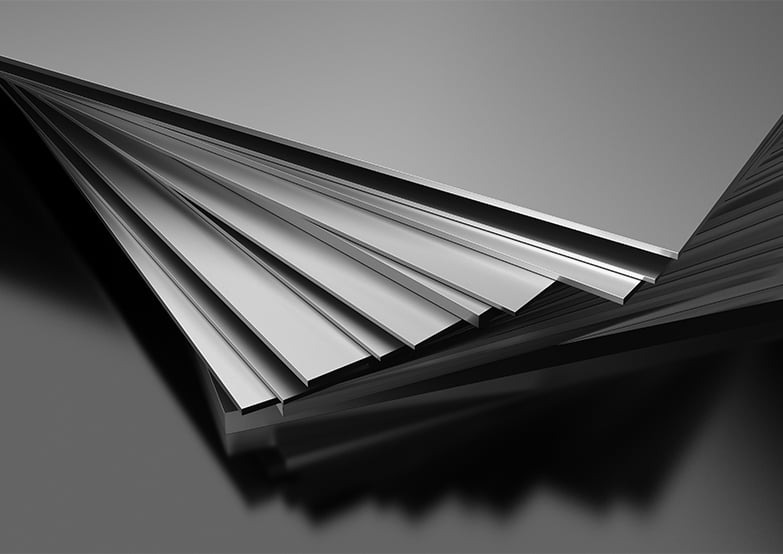

Raw materials

To ensure production speed in laser cutting and laser marking, and therefore the fulfillment of orders in the shortest time possible, we have a constantly supplied warehouse, with high quality materials always available.

We work with a large variety of materials and thicknesses, for example:

- iron from 0.40 mm to 25 mm

- stainless steel from 0.4 mm to 20 mm (surgical or hypoallergenic steel too)

- aluminum alloys from 0.40 to 10 mm

- titanium from 0.40 to 4.00 mm

- beta titanium from 0.40 mm to 3.00 mm

- Niclafor from 0.40 to 4.00 mm

- Nickel silver from 0.40 to 6 mm

The maximum dimensions that can be processed are 1500 × 3000 mm, the tolerance is +/- 0.10 mm.

The finishes

At your discretion, we can deliver raw components, with basic processing such as detachment and deburring, or completely finished, with the additional finishings chosen by you.

These include electroplating, satinizing, micro sandblasting, mirror polishing, electropolishing.

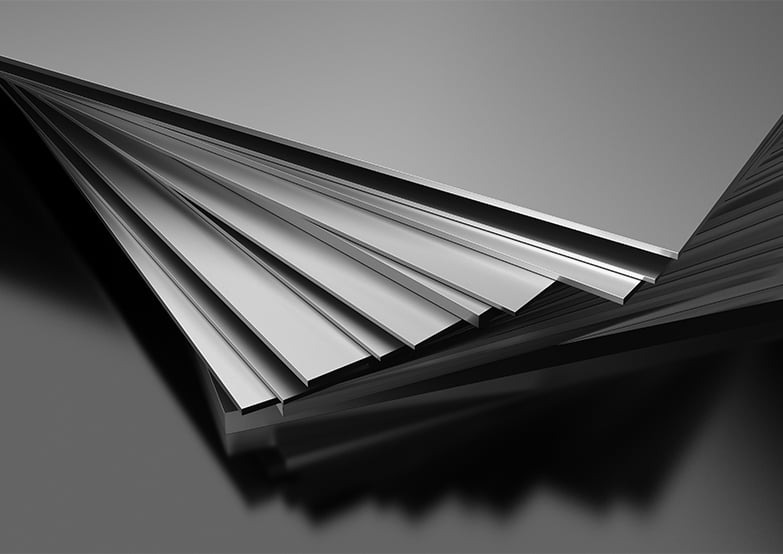

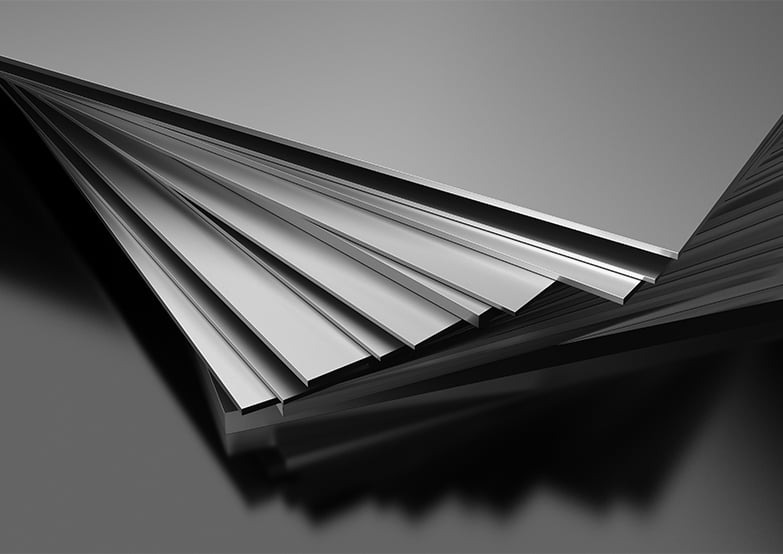

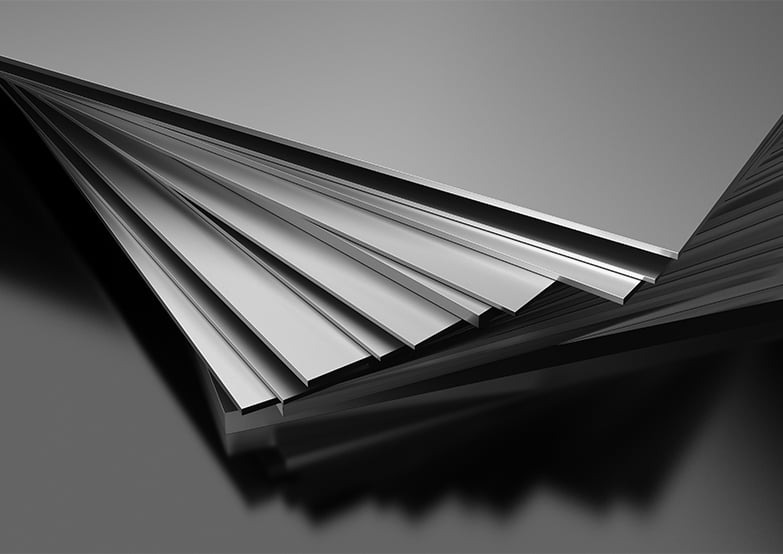

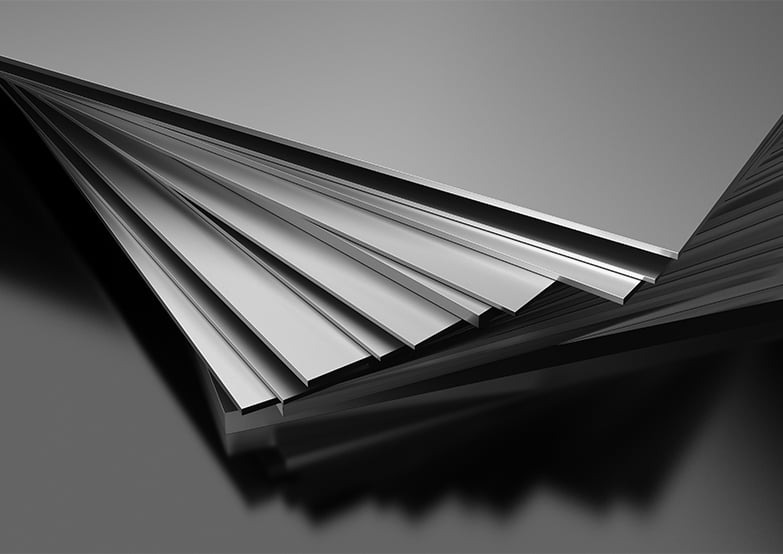

Raw materials

To ensure production speed in laser cutting and laser marking, and therefore the fulfillment of orders in the shortest time possible, we have a constantly supplied warehouse, with high quality materials always available.

We work with a large variety of materials and thicknesses, for example:

- iron from 0.40 mm to 15.00 mm

- stainless steel from 0.4 mm to 6.00 mm (surgical or hypoallergenic steel too)

- aluminum alloys from 0.40 to 5.00 mm

- titanium from 0.40 to 4.00 mm

- beta titanium from 0.40 mm to 3.00 mm

- Niclafor from 0.40 to 4.00 mm

- Nickel silver from 0.40 to 4.00 mm

The maximum dimensions that can be processed are 1500 × 3000 mm, the tolerance is +/- 0.10 mm.